What is GPR Scanning?

- Utility Detection: Locating underground pipes, cables, and utilities before excavation.

- Structural Analysis: Assessing the integrity of concrete, identifying voids, and detecting rebar placement.

- Archaeological Studies: Non-invasive exploration of buried artifacts and structures.

- Environmental Studies: Detecting underground contamination, tanks, or water sources.

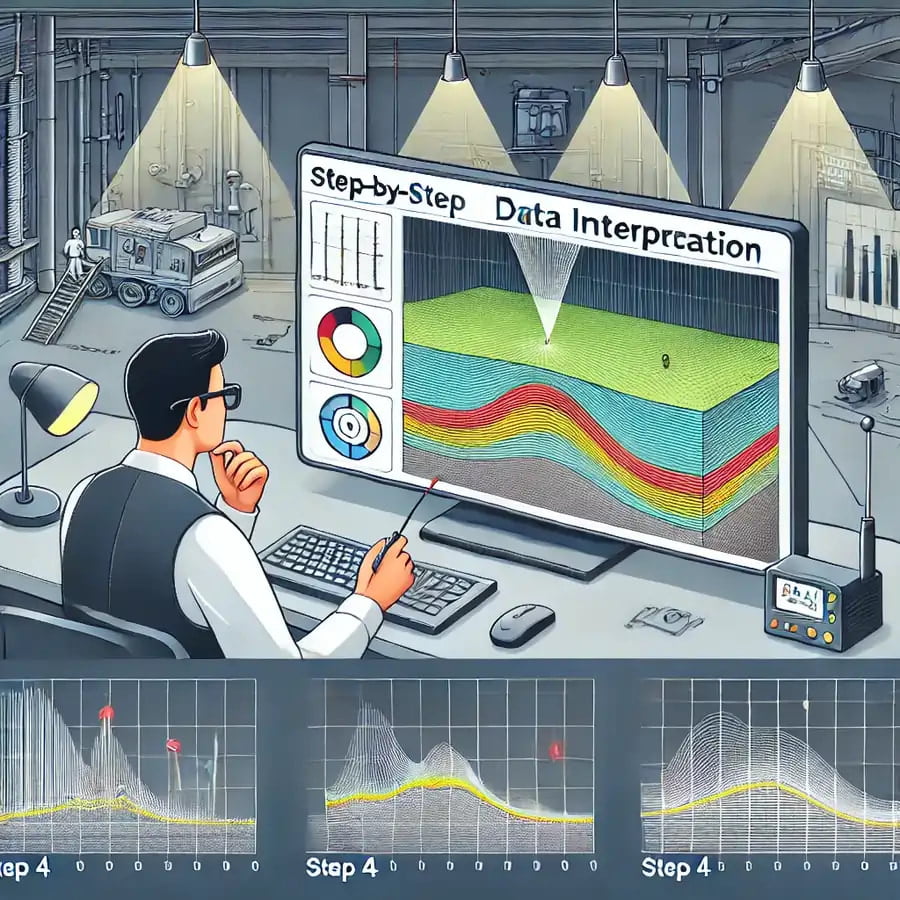

Step-by-Step Process of GPR Scanning

Site Assessment

Before starting the scanning process, a technician from Al Hadaf Concrete Scanning performs a thorough site assessment to understand the conditions of the area. This includes identifying potential high-risk zones and evaluating the soil type, moisture content, and any existing structures that may impact scanning accuracy.

Equipment Setup

Technicians from Al Hadaf use specialized GPR equipment, ranging from handheld scanners to larger vehicle-mounted units, depending on the project's size. The equipment is calibrated to suit the site's specific conditions, ensuring the most precise data collection possible.

Scanning Process

Data Interpretation

Reporting & Recommendations

Benefits of Using GPR Scanning

What to Expect When Hiring a GPR Scanning Service in Dubai

Common Challenges and How They Are Addressed

- Soil Conditions: The type and condition of the soil at a project site can significantly impact the effectiveness of GPR scanning. Soil with high moisture content, such as wet or clay-rich soils, tends to absorb radar signals more readily, making it difficult for the waves to penetrate deep enough to detect underground objects accurately. This can lead to blurred or incomplete images, affecting the precision of the scan. Al Hadaf Concrete addresses these challenges by utilizing their expertise in soil analysis and adjusting the equipment settings accordingly. Their technicians fine-tune the radar frequency, power, and scan rate to optimize performance based on the specific soil conditions at the site. They also conduct pre-scan evaluations to assess the soil composition, ensuring that the scanning equipment is set up to capture clear and accurate data, regardless of challenging soil types. With these adjustments, they can provide high-quality scans even in difficult environments.

- Interference from Dense Materials: Another significant challenge in GPR scanning comes from interference caused by dense materials like reinforced concrete, metal structures, or other underground elements. These materials can scatter or block the radar waves, resulting in "clutter" or false readings in the data. This interference can make it challenging to distinguish between actual underground features and noise caused by these materials. Our team is experienced in working with dense materials and has developed advanced techniques for mitigating interference. They use specialized software to filter out noise and focus on the critical reflections that represent true underground objects. In addition, their technicians are trained to recognize patterns in the data that may indicate interference, allowing them to adjust their analysis accordingly. This ensures that even in environments with heavy interference, Al Hadaf can provide precise and reliable results.

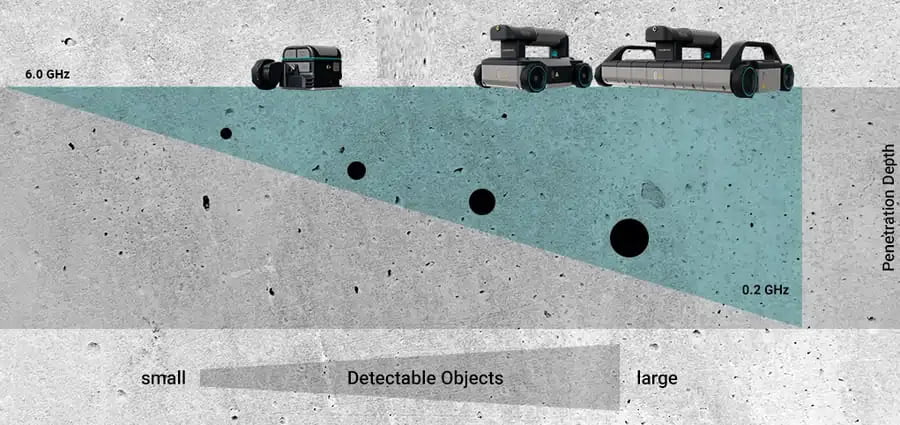

- Depth Limitations: While GPR technology is highly effective for scanning shallow to moderate depths, scanning at greater depths can pose challenges. In certain cases, deep utilities, pipes, or voids might be harder to detect due to the natural attenuation of radar waves as they travel through the ground. To address this, we uses advanced GPR equipment capable of varying frequencies, enabling deeper penetration when necessary. Higher-frequency radar waves provide better resolution for shallow scans, while lower-frequency waves penetrate deeper but may have less precision. By using a combination of frequencies, Al Hadaf’s technicians can balance depth and clarity, ensuring that both shallow and deep features are accurately captured

- Site Accessibility and Obstructions: Some construction sites are crowded with obstacles such as heavy machinery, buildings, or confined spaces, making it difficult for the GPR equipment to cover all necessary areas. In such environments, standard GPR scanning may not be sufficient to scan the entire site effectively. Al Hadaf Concrete Scanning overcomes these obstacles by using a range of GPR devices, including handheld and portable systems designed for tight or obstructed areas. Their team is skilled in adapting to difficult site conditions, ensuring that all critical areas are scanned, even if they are located in hard-to-reach spaces. This adaptability allows Al Hadaf to provide comprehensive subsurface analysis without compromising on accuracy or coverage.

- Environmental Factors: Extreme weather conditions, such as heavy rain or extreme heat, can affect the scanning process. For example, moisture from rainfall can increase the conductivity of the ground, altering how radar waves travel and reducing their ability to penetrate. On the other hand, extremely dry or arid environments may also introduce challenges, as certain ground conditions can limit the radar signal’s depth penetration. Al Hadaf Concrete Scanning addresses environmental factors by scheduling scans at optimal times and ensuring that the equipment is correctly adjusted to suit the conditions. In cases where weather or environmental conditions could affect the scan, their technicians apply calibration techniques to mitigate any potential issues, ensuring that accurate data is collected regardless of external factors.

- Human Error: Although GPR technology provides highly detailed data, human interpretation plays a significant role in analyzing the radar signals and creating subsurface maps. Misinterpretation of the data can lead to incorrect conclusions about the location or size of underground objects.The team comprises highly trained professionals with extensive experience in GPR data interpretation. They use their expertise to carefully analyze the radar reflections and cross-reference findings with site conditions, minimizing the risk of error. Additionally, Al Hadaf invests in ongoing training and the latest GPR software, ensuring that their team stays updated with the most advanced interpretation methods.

Conclusion

Ground Penetrating Radar (GPR) scanning is an essential tool for ensuring safe and efficient construction projects. Whether you're working on a major infrastructure project or a simple excavation, GPR scanning helps identify subsurface hazards and avoids costly errors. Al Hadaf Concrete Scanning is a trusted provider in Dubai, delivering accurate and reliable GPR scanning services.